How to Clean an Esd Floor

Cleaning an electrostatic discharge (ESD) floor is essential for the safety of any workplace where electronics are used. An ESD floor helps to dissipate static electricity, protecting workers and equipment from potential damage or harm. Proper cleaning and maintenance of an ESD floor will help ensure it remains safe and effective at doing its job.

The most important thing when cleaning an ESD floor is to use a product specifically designed for this type of surface. There are two key methods for cleaning such floors – sweeping with a dry mop or using a damp mop with special cleaner solution that has been proven to be safe on these surfaces. It’s also important to remember not to drag heavy items across the surface as this can cause damage; instead, lift them up whenever possible.

Furthermore, all furniture should have non-conductive feet so they don’t interfere with the electrical properties of the ESD surface itself.

- Prepare the Cleaning Solution – Create a safe, effective cleaning solution by mixing 1 gallon of water with 2 tablespoons of detergent or floor cleaner

- Sweep the Floor – Start by sweeping up any loose dirt and debris before beginning your cleaning process

- This will help you to make sure that all surfaces are clean when you’re finished

- Mop the Floor – Once you have swept up any large pieces of dirt, use a mop to apply your cleaning solution to the ESD floor in an even manner, making sure to get into any hard-to-reach areas or corners where dirt may have accumulated over time

- Allow Time for Drying – After mopping, let your ESD floor dry completely before allowing foot traffic in order to prevent slips and falls due to wet floors as well as static discharges from walking across a damp surface

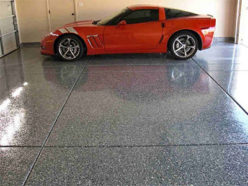

Esd Flooring

As technology advances and industries become more automated, so do the floors that they are built on. ESD (Electrostatic Discharge) Flooring is a type of flooring specifically designed to reduce static electricity build-up in industrial and commercial environments. This type of flooring has been around for decades but is becoming increasingly popular as businesses look for ways to make their work spaces safer and more efficient.

ESD flooring works by dissipating static charge away from sensitive equipment, helping to protect against damage caused by electrostatic discharge (ESD). It also helps protect workers from dangerous electrical shocks or burns due to contact with electrically charged surfaces. The materials used in ESD flooring are typically conductive, meaning that electric currents flow easily through them.

Additionally, these types of floors have special properties which ensure that any generated static charges will be safely discharged without causing discomfort or harm to personnel within the facility. Typically made from rubber or vinyl tiles embedded with metal fibers or other conductive elements, this type of floor can be laid out in an array pattern allowing it to act like a Faraday cage – protecting items inside it from external electromagnetic fields while simultaneously promoting effective grounding paths between people’s feet and the ground system beneath them. Its anti-slip surface ensures safe movement across its area regardless if there’s oil spills present — making it ideal for machine shops where safety hazards may arise due to slippery conditions on the factory floor.

This also makes ESD floors great in food processing plants where hygiene needs must be met at all times! The installation process requires certain expertise since it involves laying down multiple layers including a conductive layer underneath plus sealant strips along each edge – ensuring proper connection between tiles and reducing contamination risks associated with dust particles getting trapped between gaps during future maintenance activities such as cleaning sweeps etcetera . Furthermore , some manufacturers offer specific products meant for use indoors only; others provide outdoor versions too; hence one should carefully read up about product specifications prior ordering!

Overall , investment into quality ESD Floorings can guarantee improved worker comfort & productivity; protection against potentially hazardous situations arising due to improper/insufficient earthing systems; plus savings accrued via reduced repairs & replacements costs over time !

Credit: staticworx.com

Can You Mop Esd Floors?

Maintaining an ESD (electrostatic discharge) protected floor is essential for any workplace that handles sensitive electronic components. An ESD protected floor helps to protect these items from static electricity, which can cause damage if not mitigated. So the question arises: Can you mop ESD floors?

The answer is yes, it is possible to mop an ESD protected floor; however, there are certain considerations and safety precautions that must be taken in order to do so safely and effectively. The most important step when mopping an electrostatically-protected floor is selecting the correct cleaning solution for the specific type of surface being cleaned. It’s important to use a solution designed specifically for anti-static properties as using a general purpose cleaner may not provide adequate protection against static build up on these delicate surfaces.

Additionally, avoid using waxes or other chemical additives as they can create a coating on the surface that will attract dust particles which could interfere with static control measures over time. It’s also important to select the right equipment when mopping such floors because traditional cotton mops will generate more static than those made of synthetic materials like microfiber or rayon/polyester blends. Furthermore, remember to rinse your mop often during use and avoid wringing out excess water back into your bucket – this practice can increase electrostatic charge by transferring electrical charges between different surfaces within contact with each other (like water droplets).

Finally, ensure that all cleaning solutions used are compatible with anti-static properties before beginning work – some chemicals may actually reduce their effectiveness if mixed together! In conclusion, while it is indeed possible to safely mop an electrostatically protected floor following proper protocols outlined above – it’s always best practice whenever working around sensitive electronics components: double check compatibility ratings of all materials used as well as consult manufacturers recommendations prior starting any task involving them! And lastly make sure you wear appropriate safety attire including grounded shoes if necessary – this way you won’t only maintain cleanliness but also make sure no discharges occur due incorrect handling procedures!

How Do You Clean Esd Tiles?

When it comes to keeping your workspace safe and efficient, cleaning ESD tiles is an essential part of the process. Electrostatic discharge (ESD) tiles are used to protect sensitive equipment from static electricity that can cause damage or even destroy them. As such, it’s important that these tiles are kept clean in order to ensure their effectiveness.

The first step in cleaning ESD tiles is to vacuum the surface with a low-static vacuum cleaner attachment. This will help remove any dust and dirt particles from the tile surface before you start scrubbing. Make sure you don’t use a regular household vacuum as they often generate too much static electricity which could actually do more harm than good!

Next, dampen a microfiber cloth with water or an anti-static cleaner specifically designed for use on ESD floors like Statguard® Floorshield™ Cleaner/Polish and wipe down the entire tile surface area using circular motions until all visible dirt has been removed. If you have stubborn stains on your ESD tile flooring then you may need to scrub them gently using a soft bristled brush dipped in soapy water – just make sure not to get too deep into the grout lines otherwise this could weaken its integrity over time! Be sure also not to saturate the ESD tile with liquids as this can break down its protective coating making it less effective against static electricity build up over time.

Finally, once all excess liquid has been wiped away leave your ESD tiles dry naturally or wipe them off lightly with a fresh microfiber cloth if needed – never rub vigorously as this might create friction and generate unwanted static buildup again! And there you have it – now your workspace should be protected by clean and effective electrostatic discharge (ESD) flooring!

How Do You Clean Esd from Carpet?

Carpeting is a popular choice for many households and businesses, but it can also be vulnerable to electrostatic discharge (ESD). ESD can cause damage to electronic components or even injury to people if not properly managed. Fortunately, there are several steps you can take to clean ESD from carpeting.

The first step in cleaning ESD from carpeting is vacuuming the area with an anti-static vacuum cleaner. This will help remove any dust, dirt, and other debris that may have built up over time and could contribute to static build-up. Be sure to use an anti-static vacuum cleaner as regular ones do not reduce static electricity buildup on carpets.

Next, you’ll want to treat the affected areas with a special anti-static treatment solution designed specifically for carpets. Make sure you read all instructions carefully before applying this product so that you don’t damage your carpets in the process of trying to eliminate static electricity buildup. These solutions usually come in aerosol cans or spray bottles and should be applied directly onto the carpet fibers using a soft cloth or brush for best results.

Allow sufficient drying time before walking on or using furniture on treated areas until completely dry. Finally, after treating your carpets with an antistatic solution, it helps tremendously if your home has low relative humidity levels as well as other measures like installing conductive floorings such as rubber mats which help absorb excess current around sensitive equipment by providing a path of least resistance away from them while still maintaining safe levels of electrical grounding throughout your environment . Also make sure that all electronics are kept away from windows where they might pick up external charges due to weather conditions outside such as rain storms etc., since these too can bring unwanted currents into your space leading again towards potential risks associated with electrostatic discharge events occurring within it .

In conclusion, cleaning ESD from carpeting requires more than just vacuuming – some specialized solutions must be used in order for complete protection against damaging effects of static electricity building up inside our homes/workplaces . By following these tips & tricks provided above , one should easily manage their environment better & avoid unforeseen issues caused by uncontrolled discharges at all times .

What is Esd Flooring?

ESD flooring, or electro-static dissipative flooring, is a type of flooring that helps reduce the risk of static electricity in sensitive electronic environments. ESD floors provide a low resistance path between two points, allowing electrical charges to be safely discharged from objects and personnel. This protects equipment from any possible damage caused by an electrostatic discharge (ESD).

There are several types of ESD flooring available on the market today. The most common type is conductive vinyl tile (CVT), which consists of special materials like carbon that allow for efficient dissipation of static electricity into the ground through grounding systems such as mats and wrist straps. Conductive rubber tile is also popular; this material has tiny metal particles embedded within it to help control static discharges without compromising safety or comfort levels in the environment.

The benefits of using ESD floors are significant: they protect expensive electronic components against costly damages due to accidental shock, minimize downtime due to repair costs, reduce staff exposure to electric shocks, and improve overall safety levels in sensitive areas where electronics need extra protection Additionally, since many ESD tiles come with anti-slip surfaces and other features such as sound insulation capabilities – creating a more comfortable working environment – they can also contribute towards better employee productivity levels while reducing absenteeism rates due to illness or injury claims related to slips and falls. When installing an ESD floor system all aspects must be considered: not only do you have choose the right kind of material but you’ll also need specialist installers who understand how best to bond different elements together so that effective shielding takes place throughout your facility; furthermore if there’s any potential for moisture ingress then additional steps may be necessary such as adding sealants around edges etcetera. As always when considering anything relating either directly or indirectly with electrics it pays off greatly consulting with professionals before making any final decisions!

ESD & cleanroom flooring – FloorCare method – Instruction video | Forbo Flooring Systems

Conclusion

Hey there! Are you looking to learn how to properly clean an ESD floor? Look no further.

Today we’ll be going over the basics of cleaning and maintaining an electrostatic discharge (ESD) floor. First, it’s important to note that ESD floors are designed specifically for use in electrostatic sensitive areas like electronic manufacturing facilities or industrial workstations. To keep them functioning effectively, they need regular care and maintenance.

When it comes to cleaning your ESD floor, start by removing any large objects such as furniture or equipment from the area so that you can access all parts of the room easily. Then use a broom and dustpan to sweep away any dirt and debris on the surface of the flooring. Afterward, mop with either a damp microfiber cloth or a neutral pH cleaner approved for use on ESD floors — this will help protect their special coating from damage caused by harsh chemicals or abrasive scrubbing tools.

Finally, vacuum using a low-voltage HEPA filter machine; this will help remove static electricity built up in carpets along with small particles that could potentially interfere with electrical components if left unchecked. And there you have it! Cleaning and maintaining your ESD floor doesn’t have to be complicated; just follow these steps and you’ll be good to go in no time at all!