What is the Purpose of a Grease Duct?

A grease duct is a metal duct used to transport hot air and fumes from commercial kitchen appliances, such as griddles, ovens, deep fryers and charbroilers. The purpose of the grease duct is to provide ventilation for the appliance while collecting any hot air or smoke produced during cooking. This helps keep a safe working environment by preventing exhaust gases from entering into the kitchen area.

Additionally, it prevents flammable materials in the room from coming into contact with heat sources like pilot lights on stoves and other appliances that could potentially cause fires. By acting as a conduit for collected vapors, grease ducts also reduce odors which may arise when cooking food items in restaurants or other public facilities.

A grease duct is an integral part of the kitchen exhaust system. Its purpose is to trap and contain any grease, smoke, or steam created during the cooking process in order to prevent it from entering into other areas of the building. This helps ensure that your restaurant remains a safe and comfortable environment for both staff and customers alike.

Additionally, by preventing these contaminants from entering into other parts of the building, it also reduces fire hazards as well as potential corrosion issues with surrounding surfaces.

What is a Grease Duct

A grease duct is an enclosed piping system that is used to capture and exhaust hot greasy air from commercial cooking equipment. Grease ducts help keep the kitchen environment safe, by diverting hazardous vapors and fumes away from people in the area. They also play a role in controlling fire risk, as they can effectively contain any potential fires that may occur near or within the cooking equipment.

Credit: madonsheetmetal.com

Does Grease Duct Have to Be Welded?

Yes, grease ducts must be welded in order to ensure a secure and safe installation. Welding is the most effective way to make sure there are no leaks or weak spots that could cause fire hazards. It also ensures that air flow is not restricted due to gaps or weak connections between the ducts and other components of the ventilation system.

The welding should be done by a qualified professional who has experience working with these types of materials and systems.

How Hot Does a Grease Duct Get?

Grease ducts can reach temperatures as high as 550-750°F depending on the type of cooking equipment being used. The majority of grease ducts are lined with stainless steel or aluminized steel and have a fire resistant insulation installed to help protect combustibles from heat damage. To prevent fires, all grease ducting must be cleaned regularly in order to remove any built up grease that could potentially ignite when heated.

Additionally, exhaust fans are usually used to draw hot air away from the building to reduce the temperature inside the duct system and make it safer for employees.

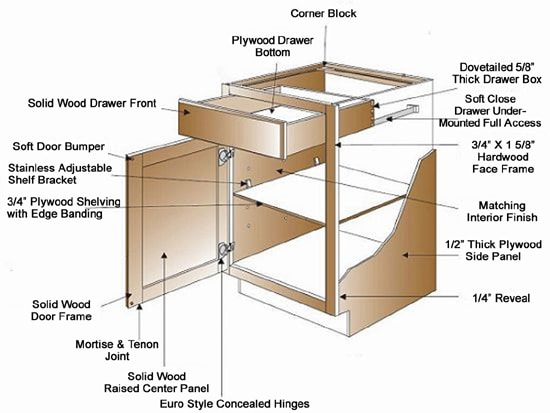

What Material is Grease Duct?

Grease ducts are typically made from either galvanized steel or stainless steel. The material used is important because it must be able to withstand the high temperatures and corrosive nature of grease-laden smoke. Galvanized steel has a protective coating that helps protect it from corrosion, however due to its thinness can easily become damaged over time and may require frequent maintenance.

Stainless steel offers superior resistance to heat and corrosion, making it a more durable option for use in grease ducts; however, stainless steel is also more expensive than galvanized steel. Depending on the application, one material may be better suited than another – so make sure you consult with an expert before making your decision!

Credit: scheblerchimney.com

What is the Slope for Grease Duct?

The slope for grease ducts is typically very important in order to ensure that waste-laden air and smoke have an easy path of travel away from the kitchen. Grease ducts should have a minimum slope of 1/4 inch per foot, with a maximum slope of 1/2 inch per foot. This allows the hot exhaust air to flow easily through the system and minimizes buildup on the walls or ceiling that could lead to fire hazards.

Additionally, it’s important to make sure there are no dips or valleys along the length of your grease duct that might allow condensation or water build up; this can also create fire hazards.

Grease Duct is usually made of 16 gauge Black Iron and always welded

Conclusion

In conclusion, grease ducts are an extremely important part of commercial kitchen ventilation systems. They help prevent the spread of fire and smoke by collecting and exhausting oil, fat, and other combustible materials from cooking appliances. Grease ducts also ensure safe air quality by preventing backdrafting of exhaust gases into the building interior.

All together, grease ducts make kitchens safer for employees and customers alike while ensuring proper ventilation to keep the area comfortable year-round.