What Do You Need For A Hot Tap?

A hot tap is a procedure used to add additional pipelines or connections to existing pipes without having to shut them down. It is a complex process that requires specialized equipment and trained personnel to ensure the safety of the operation. To successfully complete a hot tap, one must have the proper tools and supplies, such as a hot tap machine, tapping sleeves, cutting tools, and pressure-testing equipment. Additionally, it is important that the personnel involved are properly trained and certified in hot-tapping procedures in order to ensure the safety of the project.

Definition of a Hot Tap

A Hot Tap is a process by which a connection can be made to a pressurized system while it is in operation. It is a specialized procedure that requires the use of specific tools and techniques to ensure safety and efficiency. This process is commonly used in industries such as plumbing, chemical, and oil and gas, and involves drilling a hole in an operating pipe or vessel so that a permanent connection can be established. Hot Taps are generally used to add, remove, or modify components in a system, or to provide an access point for the removal of liquids. Safety is paramount when performing a Hot Tap, and should only be performed with the proper equipment and training to avoid any potential risks.

Benefits of Installing a Hot Tap

A hot tap is a great addition to any kitchen or bathroom. It provides hot water on demand and can be used to make tea, coffee, or hot chocolate quickly and easily. It also eliminates the need to wait for a pot of boiling water to heat up. In addition, installing a hot tap can save both time and money. Hot taps use less energy than boiling water on the stove or in a kettle, so they can help reduce your energy bills. They are also easier to maintain and keep clean than traditional hot water heaters. With a hot tap, you can enjoy instant hot water anytime without the hassle of waiting for it to heat up.

Types of Hot Taps

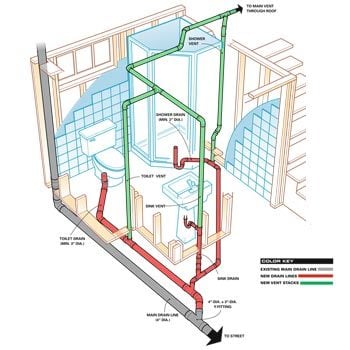

Hot taps are a type of plumbing technique used to make a connection to an existing pipe, while the system is still in service. They are used to repair, replace, or install a new connection without having to shut down the water or gas supply. Hot taps are divided into two categories: wet taps and dry taps. Wet taps use a drill bit to make a hole in a pipe that is already full of liquid or gas, while dry taps require the pipe to be empty before drilling. Both types involve the use of a specialized valve, which is designed to contain the pressure of the liquid or gas while the connection is being made. Hot taps are used for a variety of purposes, including installing pressure regulators, bypasses, or isolation valves, as well as for making connections to sprinkler systems, fountains, swimming pools, or other fixtures. They provide an efficient way to make repairs and add new connections without having to turn off the water or gas supply.

Necessary Tools and Equipment for Hot Tapping

Hot tapping is a technique used in the pipeline industry for safely making a connection to an existing pipeline or pressure vessel while it is still in service. It is often used to install branch connections, test ports, or add instrumentation. In order to safely and effectively perform hot tapping, it is important to have the right tools and equipment. These include a hot tap machine, a tapping adapter, a drill bit, a pressure gauge, a valve, a cutting and beveling tool, a facing tool, and safety equipment such as a respirator, safety glasses, and hearing protection. When purchasing these tools and equipment, it is important to make sure they are of the highest quality and designed for the specific job being performed. Hot tapping can be a dangerous job, and having the right tools and equipment is essential for a successful job.

Steps Involved in Making a Hot Tap

Making a hot tap is a relatively straightforward process that can be done in a few simple steps. First, the hot tap machine is set up on the pipe or vessel that needs to be tapped. Second, the machine is then secured in place and the pilot hole is drilled into the pipe or vessel. Third, the hot tap valve is installed into the pilot hole. Fourth, the hot tap machine is connected to a power source and the hot tap is started. Fifth, the pipe or vessel is then cut and the tap is removed. Finally, the hot tap valve is tested and the system is brought back up to pressure. With a few simple steps, you can make a hot tap and ensure your system is running smoothly.

Safety Considerations for Hot Tapping

Hot tapping is a complex process that should only be undertaken by experienced professionals. It requires the use of specialized equipment to safely tap into pressurized pipes and systems and involves risks such as fire, explosion, and chemical exposure. To ensure safe operation, it is important to consider the following safety considerations prior to hot tapping: proper training, safety equipment, emergency shutoff valves, leak detection equipment, and personal protective equipment. Additionally, all safety protocols must be followed to ensure that the hot-tapping process is conducted safely and efficiently. Proper planning and preparation are essential to the successful execution of any hot-tapping project, and the safety of those involved should always be the top priority.

Common Mistakes with Hot Tapping

Hot tapping, also known as pressure tapping, is a process for connecting pipelines, tanks, and other pressurized vessels without interrupting the system or its contents. While hot tapping is a common practice in the industrial world, it is important to understand the potential risks and mistakes that can occur. Common mistakes when hot tapping includes failing to properly prepare the site, using the wrong type of equipment, or not accounting for the pressure of the system. Other potential pitfalls include not properly measuring the depth of the tap, not using the right hot tap adapter, or failing to properly clean the site before beginning. By understanding these common mistakes, you can ensure that your hot-tapping projects are completed efficiently and safely.

Troubleshooting Tips for Hot Tapping

Hot tapping is a valuable industrial tool that allows for the connection of new pipes to existing piping systems without having to shut down the system. However, it does come with some challenges that must be taken into account. This blog provides troubleshooting tips for hot tapping, so you can get the most out of this valuable tool. We’ll cover different techniques for safely installing and removing taps, how to identify common problems, and helpful tools to help you get the job done right. We’ll also provide advice on maintaining and inspecting your hot taps to ensure they’re working properly. With our help, you’ll be able to hot tap with the confidence and peace of mind that comes with knowing that your taps are safely and properly installed.

Conclusion

The hot tap is a great way to access pressurized piping systems without having to shut down the system. To perform a hot tap, you need a hot tap machine, a drill, a valve, and a fitting. It is important to use the right type of equipment for the job, as using the wrong equipment can lead to safety hazards and other risks. Additionally, it is important to take all necessary safety precautions when performing a hot tap to ensure that the job is done properly and without any dangerous incidents.